What is a Continuous isothermal quenching heating furnace? Introduction to the advantages and characteristics of the Forging furnace

Continuous isothermal quenching heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,widely used inmetallurgy,light industry,aerospace,machinery,surface treatment and other industries。The following is to introduce the Continuous isothermal quenching heating furnace:

1、Brief introduction of Continuous isothermal quenching heating furnace

Continuous isothermal quenching heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,has been favored by more and more customers.。

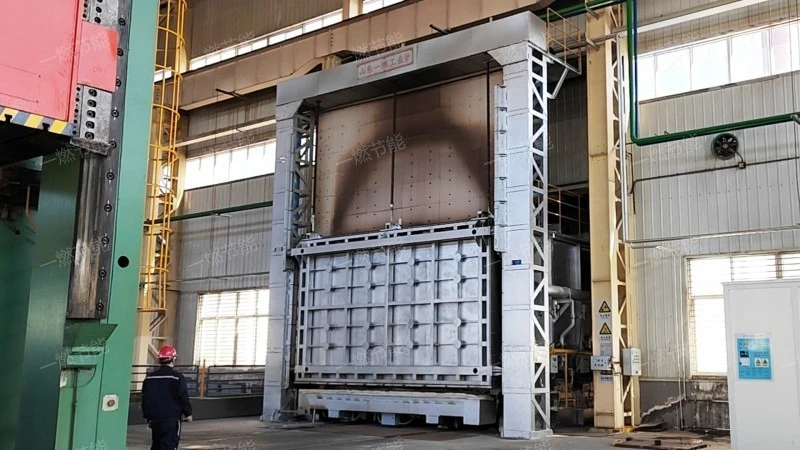

Continuous isothermal quenching heating furnace

2、Continuous isothermal quenching heating furnace characteristics

The Continuous isothermal quenching heating furnace features are as follows:

- Strong adaptability

- Easy to control

- Easy to maintain

- Efficient heating

- Stable and reliable

The Continuous isothermal quenching heating furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The structural design of the Continuous isothermal quenching heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Continuous isothermal quenching heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Continuous isothermal quenching heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Continuous isothermal quenching heating furnace

3、Functional advantages of Continuous isothermal quenching heating furnace

Continuous isothermal quenching heating furnaces have the following advantages.

- clean energy

- Multiple fuel options

- Intelligent control

- Improve product quality

- Wide application range

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

Although the Continuous isothermal quenching heating furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Continuous isothermal quenching heating furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

Because the Continuous isothermal quenching heating furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The Continuous isothermal quenching heating furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Continuous isothermal quenching heating furnace

4、Continuous isothermal quenching heating furnace function

Continuous isothermal quenching heating furnaceit has the functions of quench, heat treatment, hardening and tempering, quench and normalizing,Cheap and high quality。

Continuous isothermal quenching heating furnace

5、Continuous isothermal quenching heating furnace application

Continuous isothermal quenching heating furnaces have the following purposes.

- Metal melting and casting

- Metal heat treatment

- Improve production efficiency

- Energy conservation and environmental protection

- Metal forging heating

Although it is mainly used for forging heating, some types of Continuous isothermal quenching heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, Continuous isothermal quenching heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Continuous isothermal quenching heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Continuous isothermal quenching heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Continuous isothermal quenching heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Continuous isothermal quenching heating furnace

6、Continuous isothermal quenching heating furnace price

The Continuous isothermal quenching heating furnace price is introduced as follows:

- Different regions

- specifications and models

- Overall configuration

- raw material

- brand

One-combustion energy savingJinan, Shandong province, the transportation is convenient, and the corresponding cost of transporting Continuous isothermal quenching heating furnace is low, which reduces the cost of selling Continuous isothermal quenching heating furnace by manufacturers, and the price will also decrease.

The same equipment, even with different models and different configurations, has different investment costs, so the price will be different.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Continuous isothermal quenching heating furnace are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing Continuous isothermal quenching heating furnace, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Different brands of products in the same series have more or less differences in product prices, and different brands of Continuous isothermal quenching heating furnace have more or less differences in price.

Continuous isothermal quenching heating furnace

Continuous isothermal quenching heating furnaceWidely used inMetal melting and casting,Metal tempering,Improve production efficiency,Metal forging heating,Energy conservation and environmental protection and so on,It is a forging heating device using gas as fuel.,is a Continuous isothermal quenching heating furnace。

Related recommendation

-

Introduction to Box type mold quenching furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Car industrial annealing furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Dual car resistance heating furnace and Trolley resistance heating furnace working principle

2025-5-27 -

What is a Regenerative burner tube roasting furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Tempered annealing furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Trolley ring heating furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Double door dual gas trolley furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Side entry and side exit stepper industrial furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Gas trolley furnace in heat treatment workshop and forging furnace advantages and features

2025-5-27 -

What is a Electric industry annealing furnace? Introduction to the advantages and characteristics of Trolley resistance heating furnace functions

2025-5-27