Introduction to Gas storage through furnace, Forging furnace advantages, characteristics and principles

Gas storage through furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the product looks beautiful.,It has a wide range of uses, including Metal forging heating, Energy conservation and environmental protection, Metal heat treatment, Improve production efficiency and Energy conservation and environmental protection。The following is to introduce the Gas storage through furnace:

1、Brief introduction of Gas storage through furnace

Gas storage through furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,is a Gas storage through furnace,it is an ideal choice for customers to buy Gas storage through furnace。

Gas storage through furnace

2、Structural characteristics of Gas storage through furnace

The Gas storage through furnace has the following structure

- Waste heat recovery system

- combustor

- Radiation chamber

- Waste heat recovery system

- combustor

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The heat load of the main place for Gas storage through furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Gas storage through furnace

3、Gas storage through furnace application

Gas storage through furnaces have the following purposes.

- Metal heat treatment

- Metal melting and casting

- Metal forging heating

- Metal forging heating

- Metal heat treatment

In addition to forging heating, Gas storage through furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Although it is mainly used for forging heating, some types of Gas storage through furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Gas storage through furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Gas storage through furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Gas storage through furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Gas storage through furnace

4、Gas storage through furnace function

Gas storage through furnaceit has the functions of temper, Forging heating, Casting heating, anneal and normalizing,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.。

Gas storage through furnace

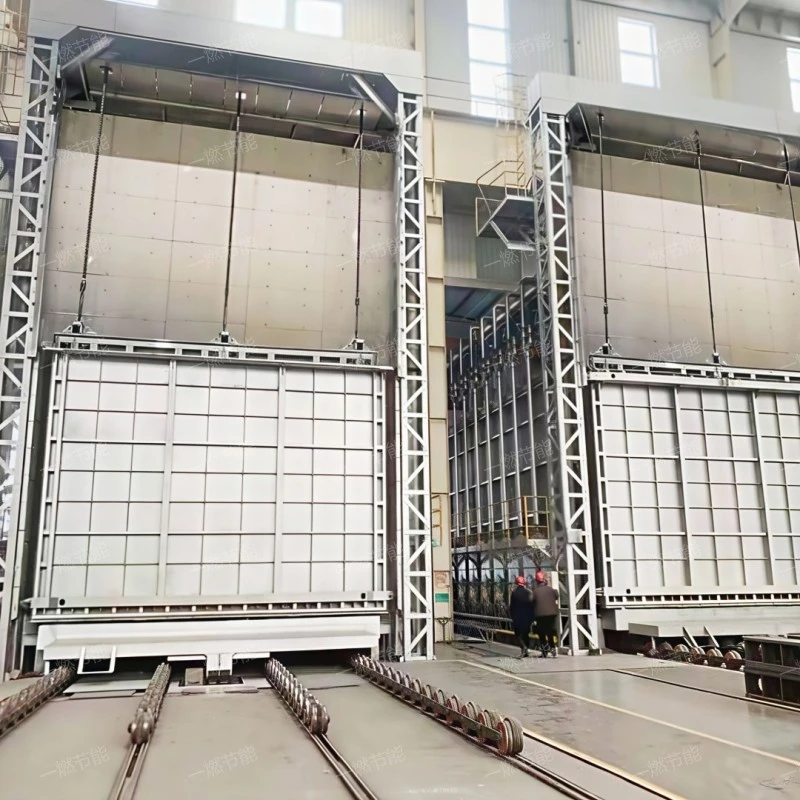

5、Gas storage through furnace HD real picture

Various styles and styles of Gas storage through furnace, complete models, for you to choose at will.。

Gas storage through furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、How much is the Gas storage through furnace?

The Gas storage through furnace price is introduced as follows:

- market competition

- technology

- Quality advantages and disadvantages

- product function

- raw material

The market has great fluctuation, which is also the key factor that leads to the imbalance and instability of supply and demand, and then leads to great changes in product prices. Only after a comprehensive understanding and investigation of the market can we make a reasonable decision, and then we can formulate a Gas storage through furnace price sales plan that customers are satisfied with, and the main reason for its price rationality is also reflected here.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Gas storage through furnace will vary greatly. One-combustion energy saving attaches great importance to the quality of products, and the formulation of prices is also reasonable.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Gas storage through furnace

Gas storage through furnaceis a common Gas storage through furnace,it has the characteristics of Stable and reliable, Strong adaptability, Stable and reliable, energy saving and environmental protection and energy-efficient,multifunctional, with functions such as hardening and tempering, Forging heating, heat treatment, Casting heating and normalizing。

Related recommendation

-

What is a Stick type roasting furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Stick style rapid spheroidization annealing furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Multi functional continuous heat treatment industrial furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

What is a High temperature roller furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Natural gas roller bottom furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

台车式模具预热炉

2023-07-16 -

Introduction to Rotary heat treatment heating furnace, how much is the price of the forging furnace?

2025-5-27 -

Introduction to Natural gas regenerative through heating furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Stick style rapid spheroidization annealing furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

What is a Regenerative chain furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27