Introduction to Roller bottom spheroidization heat treatment furnace and heating furnace structure principle

Roller bottom spheroidization heat treatment furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,Commonly used inImprove production efficiency,Energy conservation and environmental protection,Metal forging heating,Improve production efficiency,Metal forging heating and so on,it has the functions of Forging heating, Casting heating, quench, hardening and tempering and anneal。The following is to introduce the Roller bottom spheroidization heat treatment furnace:

1、Brief introduction of Roller bottom spheroidization heat treatment furnace

Roller bottom spheroidization heat treatment furnaceIt is a forging heating device using gas as fuel.,the advantage is Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.,customizable。

Roller bottom spheroidization heat treatment furnace

2、Roller bottom spheroidization heat treatment furnace characteristics

The Roller bottom spheroidization heat treatment furnace features are as follows:

- energy saving and environmental protection

- Easy to control

- Stable and reliable

- Easy to maintain

- Easy to control

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Roller bottom spheroidization heat treatment furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The combustion system and ventilation system of the Roller bottom spheroidization heat treatment furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Roller bottom spheroidization heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The structural design of the Roller bottom spheroidization heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

Roller bottom spheroidization heat treatment furnace

3、Advantages of Roller bottom spheroidization heat treatment furnace principle

Roller bottom spheroidization heat treatment furnaceat runtime,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,the product looks atmospheric.,It is an efficient, energy-saving and environment-friendly metal heating device.。

Roller bottom spheroidization heat treatment furnace

4、Roller bottom spheroidization heat treatment furnace function

Roller bottom spheroidization heat treatment furnacemultifunctional, with functions such as quench, temper, Forging heating, Casting heating and normalizing,it has the structure of Radiation chamber, ventilation system, recovery of waste heat, combustor and convection chamber,Roller bottom spheroidization heat treatment furnaceThe structural design is simple, novel and special.,the main features are Easy to control, Strong adaptability, energy saving and environmental protection, Easy to maintain and Stable and reliable,the product looks beautiful.,be loved by our customers.。

Roller bottom spheroidization heat treatment furnace

5、Roller bottom spheroidization heat treatment furnace price

The Roller bottom spheroidization heat treatment furnace price is introduced as follows:

- Service factor

- product configuration

- Less intermediate links

- geographical position

- Product technology

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Roller bottom spheroidization heat treatment furnace price and service can meet the actual needs of customers.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Roller bottom spheroidization heat treatment furnace, which is beyond doubt. One-combustion energy saving makes every product with great care in the attitude of being highly responsible to customers, so the price of One-combustion energy saving Roller bottom spheroidization heat treatment furnace is reasonable for products with the same configuration.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. One-combustion energy saving the address is located at:Shandong(Province), where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

Roller bottom spheroidization heat treatment furnace

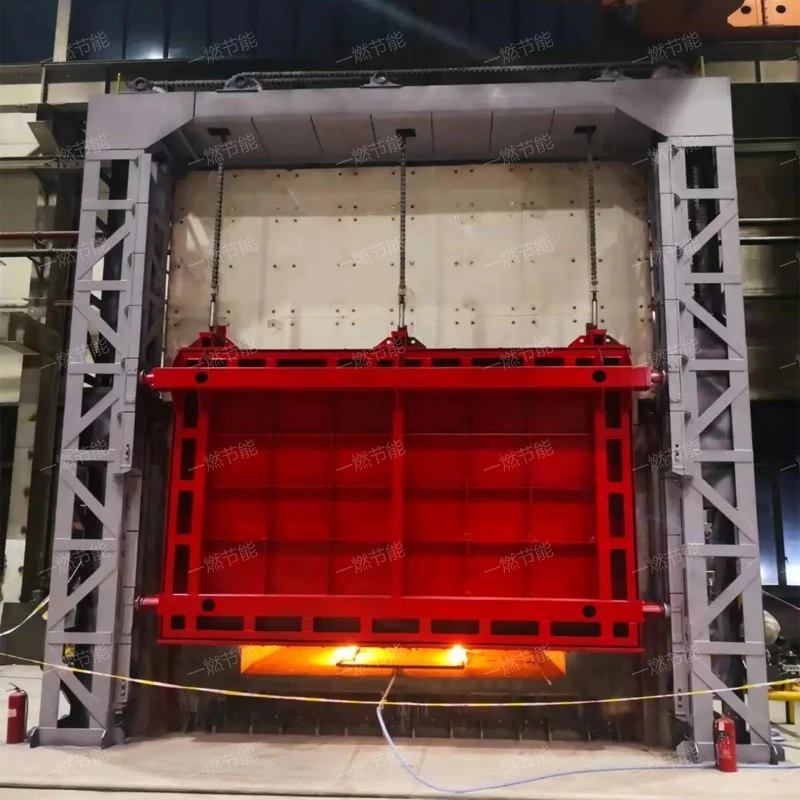

6、High-definition map of One-combustion energy saving workshop

The finished products of the Roller bottom spheroidization heat treatment furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Roller bottom spheroidization heat treatment furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Roller bottom spheroidization heat treatment furnaceit has the functions of heat treatment, hardening and tempering, anneal, Casting heating and normalizing,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,it can be used in pharmacy, electron, building materials, automobile, war industry and other industries。

Related recommendation

-

Introduction to Environmentally friendly through forging furnace and Forging furnace working principle

2025-5-27 -

What is a Denitrification of strip steel heating furnace? Introduction to the principle of SCR denitration system structure

2025-5-27 -

What is a Large box furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Automatic loading and unloading heat treatment furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Round tube quenching furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Automatic loading and unloading resistance furnace and Trolley resistance heating furnace working principle

2025-5-27 -

Introduction to Industrial tube annealing furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Box type heat treatment furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Fully automatic industrial heating furnace and heating furnace structure principle

2025-5-27 -

What is a Environmentally friendly box type heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27