Introduction to Intermediate heat treatment electric heating furnace, how much is the price of the Trolley electric furnace?

Intermediate heat treatment electric heating furnaceis an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.,the advantage is The service life is long, and the key components such as furnace body and electric heating element are made of high quality materials, which has high durability and stability.、The temperature uniformity is good, and the temperature distribution in the Intermediate heat treatment electric heating furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.、Simple operation, relatively simple Intermediate heat treatment electric heating furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、The electrothermal conversion efficiency is high, and the Intermediate heat treatment electric heating furnace can efficiently convert electric energy into heat energy, which is higher than the thermal efficiency of the traditional flame furnace.、The maintenance cost is low, the Intermediate heat treatment electric heating furnace structure is relatively simple, the maintenance is relatively convenient, and the failure rate is relatively low, which is helpful to reduce the maintenance cost.,is a Intermediate heat treatment electric heating furnace,the product looks atmospheric.,it can be used in fireproofing, machinery, Special material, electron, building materials and other industries。The following is to introduce the Intermediate heat treatment electric heating furnace:

1、Brief introduction of Intermediate heat treatment electric heating furnace

Intermediate heat treatment electric heating furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,the main features are energy-efficient, High flexibility, Environmental protection and safety, Easy to operate and maintain. and Strong adaptability。

Intermediate heat treatment electric heating furnace

2、Intermediate heat treatment electric heating furnace structure

The Intermediate heat treatment electric heating furnace structure is introduced as follows:

- furnace chamber

- heating element

- Temperature control system

- base

- thermal insulation (material)

Refractory materials are built in the furnace to withstand high temperature.

Electric heating elements (such as Fe-Cr-Al electric heater, Ni-Cr electric heater, silicon carbide rod, etc.) are the core components for generating heat.

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

Used to support the whole Intermediate heat treatment electric heating furnace and ensure its stability.

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

Intermediate heat treatment electric heating furnace

3、Intermediate heat treatment electric heating furnace function

Intermediate heat treatment electric heating furnacemultifunctional, with functions such as anneal, temper, Forging heating, hardening and tempering and heat treatment,widely used in building materials, New material development, electron, fireproofing, machinery and other fields,is a Intermediate heat treatment electric heating furnace newly developed by One-combustion energy saving。

Intermediate heat treatment electric heating furnace

4、Intermediate heat treatment electric heating furnace use

The purpose of Intermediate heat treatment electric heating furnace is introduced as follows:

- Metal heat treatment

- Metal melting and casting

- powder metallurgy

- Ceramic and glass industries

- New material development

Such as quenching, normalizing, annealing, tempering, etc.

Used for melting low melting point metals and alloys.

Used for sintering and heat treatment of powder.

Used for baking and annealing of ceramics and glass.

Used for synthesis and heat treatment of special materials and new materials.

Intermediate heat treatment electric heating furnace

5、How much is the Intermediate heat treatment electric heating furnace?

The Intermediate heat treatment electric heating furnace price is introduced as follows:

- Cost input

- Brand strength

- product function

- Sales model

- product configuration

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

At present, there are various brands of Intermediate heat treatment electric heating furnace in Jinan, Shandong province. The performance, quality and after-sales of products under different brands are different, and the prices of Intermediate heat treatment electric heating furnace are different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

The difference in Intermediate heat treatment electric heating furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Intermediate heat treatment electric heating furnace

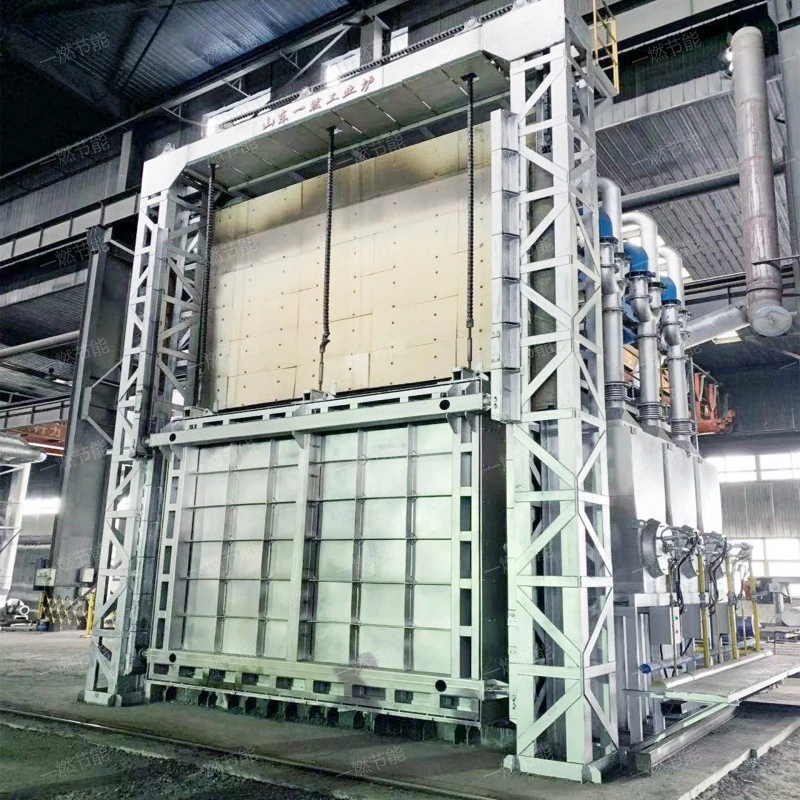

6、One-combustion energy saving workshop real shot

The finished products of the Intermediate heat treatment electric heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Intermediate heat treatment electric heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Intermediate heat treatment electric heating furnacewidely used inglass,New material development,Special material,metallurgy,pottery and porcelain and other industries,Mainly used foranneal,Metal heat treatment heating,Melting of low melting point metal,hardening and tempering andnormalizing,features include Long service life, Fast heating speed, Easy to control, Electrothermal conversion efficiency and Low maintenance cost。

Related recommendation

-

台车双门焙烧炉

2023-05-31 -

Introduction to Regenerative burner tube heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Chain type aluminum rod heating furnace and forging furnace working principle

2025-5-27 -

Introduction to Stress relief annealing heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Energy saving chain annealing furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Quenching well tube furnace and heating furnace structure principle

2025-5-27 -

What is a Regenerative natural gas box furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Deep well bright heat treatment furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Chain track aluminum rod heating furnace and Forging furnace working principle

2025-5-27 -

What is a Continuous heating quenching heat treatment furnace? Introduction to the principle of forging furnace structure

2025-5-27