What is a Resistance heating mold shell baking furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric furnace

Resistance heating mold shell baking furnaceis an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.,it is an ideal choice for customers to buy Resistance heating mold shell baking furnace。

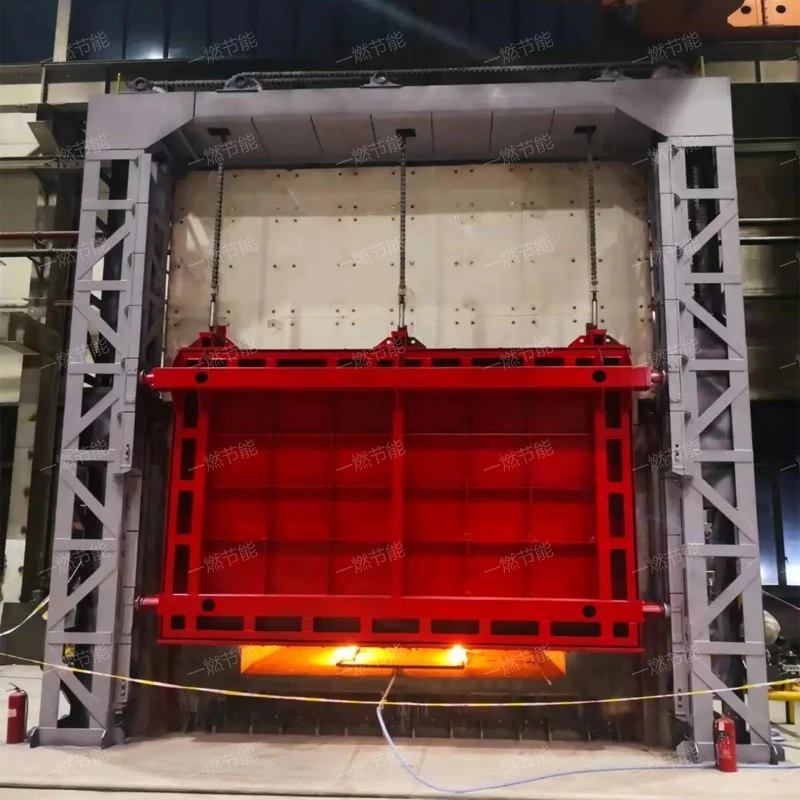

1、Brief introduction of Resistance heating mold shell baking furnace

Resistance heating mold shell baking furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,it is widely used inNew material development,electron,building materials,Special material,metallurgy and other industries,The electrothermal conversion efficiency is high, and the Resistance heating mold shell baking furnace can efficiently convert electric energy into heat energy, which is higher than the thermal efficiency of the traditional flame furnace.、The maintenance cost is low, the Resistance heating mold shell baking furnace structure is relatively simple, the maintenance is relatively convenient, and the failure rate is relatively low, which is helpful to reduce the maintenance cost.、Environmental protection, energy saving, no pollutants generated by fuel combustion, in line with environmental protection requirements; At the same time, due to high thermal efficiency, energy consumption is relatively low.、Fast heating, the Resistance heating mold shell baking furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, the heating Resistance heating mold shell baking furnace is directly heated, and the current directly passes through the material, so the heating speed is faster.、Easy to control, accurate temperature control, and easy to realize automatic control.,be loved by our customers.。

Resistance heating mold shell baking furnace

2、Resistance heating mold shell baking furnace characteristics

The Resistance heating mold shell baking furnace features are as follows:

- Fast heating speed

- Electrothermal conversion efficiency

- Strong adaptability

- Strong adaptability

- Environmental protection and energy saving

The heating speed of the Resistance heating mold shell baking furnace is relatively fast, especially in the direct heating Resistance heating mold shell baking furnace, the current directly passes through the material, which makes the material heat up rapidly.

Resistance heating mold shell baking furnaces can efficiently convert electric energy into heat energy. Usually, the electric heating conversion efficiency can reach 50-80%, which is higher than that of traditional flame furnaces.

The Resistance heating mold shell baking furnace can be customized according to different heating requirements and is suitable for heating materials of various shapes and sizes.

The Resistance heating mold shell baking furnace can be customized according to different heating requirements and is suitable for heating materials of various shapes and sizes.

The Resistance heating mold shell baking furnace has no pollutants produced by fuel combustion, which meets the requirements of environmental protection. At the same time, energy consumption is relatively low because of its high efficiency of electrothermal conversion.

Resistance heating mold shell baking furnace

3、Resistance heating mold shell baking furnace structure

The Resistance heating mold shell baking furnace structure is introduced as follows:

- furnace shell

- eye split

- heating element

- fire door

- furnace body

The furnace shell is usually made of steel plate for protection.

It is arranged on the furnace body and used to observe the heating situation in the furnace.

The heating element is the core component of the Resistance heating mold shell baking furnace, which is responsible for converting electric energy into heat energy. Common heating elements include resistance wires, resistance bands and electric heating tubes. According to the temperature requirement and heating speed in the furnace, different types of heating elements can be selected.

The furnace Resistance heating mold shell baking furnace is the passage for operators to enter and leave the furnace, and it also plays a certain sealing role. It can effectively prevent the heat in the furnace from leaking out and the cold air from outside from entering, and ensure the stability of the temperature in the furnace.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

Resistance heating mold shell baking furnace

4、Working principle of Resistance heating mold shell baking furnace

Resistance heating mold shell baking furnacein the course of work,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,it is an ideal choice for customers to buy Resistance heating mold shell baking furnace。

Resistance heating mold shell baking furnace

5、How much is the Resistance heating mold shell baking furnace?

The Resistance heating mold shell baking furnace price is introduced as follows:

- raw material

- Manufacturer's strength

- product costs

- After-sales service level

- Brand strength

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

The nature of the manufacturer can also greatly affect the price of the Resistance heating mold shell baking furnace. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

The production cost is mainly the purchase of raw materials. One-combustion energy saving attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, One-combustion energy saving strives to reduce the input cost of products, and customers are very satisfied with this.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Resistance heating mold shell baking furnace price and service can meet the actual needs of customers.

At present, there are various brands of Resistance heating mold shell baking furnace in Jinan. The performance, quality and after-sales of products under different brands are different, and the prices of Resistance heating mold shell baking furnace are different.

Resistance heating mold shell baking furnace

6、company strength

The company has many years of Resistance heating mold shell baking furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Resistance heating mold shell baking furnaceSimple operation, relatively simple Resistance heating mold shell baking furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、The safety is high, and the Resistance heating mold shell baking furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.、Long service life. The main parts of the Resistance heating mold shell baking furnace, such as electric heating elements and furnace, are made of high-quality materials, which have high durability and stability and long service life.、Pollution-free emission, the Resistance heating mold shell baking furnace does not produce pollutants such as smoke, waste gas, etc. in the working process, which meets the requirements of environmental protection and helps to protect the production environment.、Strong customization, the Resistance heating mold shell baking furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.,is a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.。

Related recommendation

-

Introduction to Preheating burner trolley heating furnace, how much is the price of the heating furnace?

2025-5-27 -

井式台车炉

2023-09-07 -

Introduction to Plate chain quenching heat treatment furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Automatic temperature control tube quenching furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Gas trolley forging heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Natural gas thermal storage tubular roaster, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Intelligent temperature control electric furnace, introduction to Trolley electric heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Double door gas trolley furnace and heating furnace working principle

2025-5-27 -

What is a Automatic temperature regulating gas trolley furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Carbon fiber trolley heating furnace? heating furnace specifications, models, and parameters

2025-5-27