Introduction to Casting normalizing gas trolley furnace, introduction to forging furnace function advantages and characteristics

Casting normalizing gas trolley furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

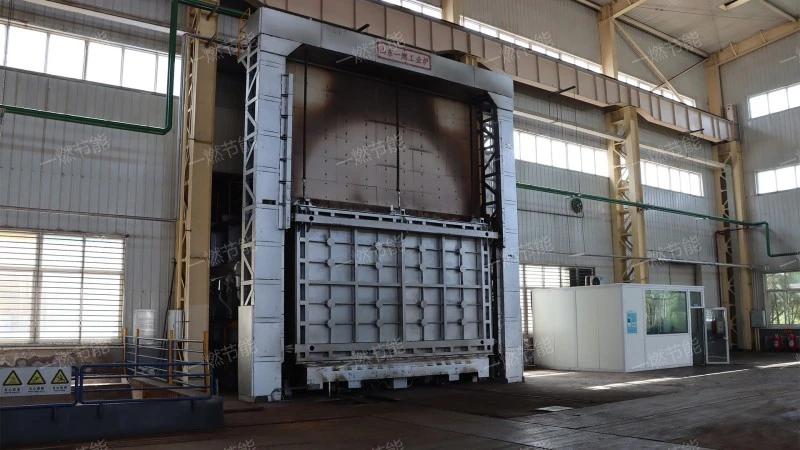

1、Brief introduction of Casting normalizing gas trolley furnace

Casting normalizing gas trolley furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it is usually composed of ventilation system, combustor, convection chamber, Radiation chamber and Radiation chamber,productThe structural design is simple, novel and special.,the product looks atmospheric.。

Casting normalizing gas trolley furnace

2、Casting normalizing gas trolley furnace characteristics

The Casting normalizing gas trolley furnace features are as follows:

- Strong adaptability

- Easy to maintain

- Efficient heating

- energy saving and environmental protection

- Strong adaptability

The Casting normalizing gas trolley furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The structural design of the Casting normalizing gas trolley furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Casting normalizing gas trolley furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Casting normalizing gas trolley furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The Casting normalizing gas trolley furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

Casting normalizing gas trolley furnace

3、Casting normalizing gas trolley furnace function

Casting normalizing gas trolley furnaceit has the functions of quench, hardening and tempering, heat treatment, temper and Casting heating,features include Strong adaptability, Easy to maintain, energy saving and environmental protection, energy-efficient and Easy to control。

Casting normalizing gas trolley furnace

4、Casting normalizing gas trolley furnace structure

The Casting normalizing gas trolley furnace structure is introduced as follows:

- combustor

- Waste heat recovery system

- furnace chamber

- ventilation system

- combustor

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

A space for holding metallic materials for heating.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Casting normalizing gas trolley furnace

5、Casting normalizing gas trolley furnace function

Casting normalizing gas trolley furnacemultifunctional, with functions such as hardening and tempering, heat treatment, anneal, temper and quench,the product looks beautiful.,at work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,be of high quality。

Casting normalizing gas trolley furnace

6、Casting normalizing gas trolley furnace price advantage

The Casting normalizing gas trolley furnace price is introduced as follows:

- marketing channel

- market

- brand

- company strength

- product function

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

The Casting normalizing gas trolley furnace market is always a fluctuating variable value. When the demand for this product in the market is far greater than the supply, the product price will be higher. On the other hand, when the market demand is much less than the supply, manufacturers are eager to sell their products and lower their prices appropriately.

Different brands of products in the same series have more or less differences in product prices, and different brands of Casting normalizing gas trolley furnace have more or less differences in price.

There are many Casting normalizing gas trolley furnace manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Casting normalizing gas trolley furnace

Casting normalizing gas trolley furnaceat runtime,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,it has the functions of Forging heating, normalizing, Casting heating, hardening and tempering and temper。

Related recommendation

-

What is a Continuous isothermal quenching heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Protective gas trolley forging heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Automatic lifting resistance heating furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

Introduction to Denitrification system for strip steel heating furnace and SCR flue gas denitrification structure principle

2025-5-27 -

What is a Rapid quenching heat treatment heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

台车高温炉

2023-05-07 -

What is a Trolley type tempering furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Dual car resistance furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

Introduction to Trolley solidification furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Low temperature absorption SCR denitrification, advantages, characteristics and principles of SCR denitration

2025-5-27