What is a End in end out step heat treatment furnace? Introduction to the Working Principle of Forging furnace

End in end out step heat treatment furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,at work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,multifunctional, with functions such as quench, Forging heating, temper, normalizing and Casting heating,Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.,is a kind of high quality and low price End in end out step heat treatment furnace。

1、Brief introduction of End in end out step heat treatment furnace

End in end out step heat treatment furnaceIt is a forging heating device using gas as fuel.,it is an ideal choice for customers to buy End in end out step heat treatment furnace。

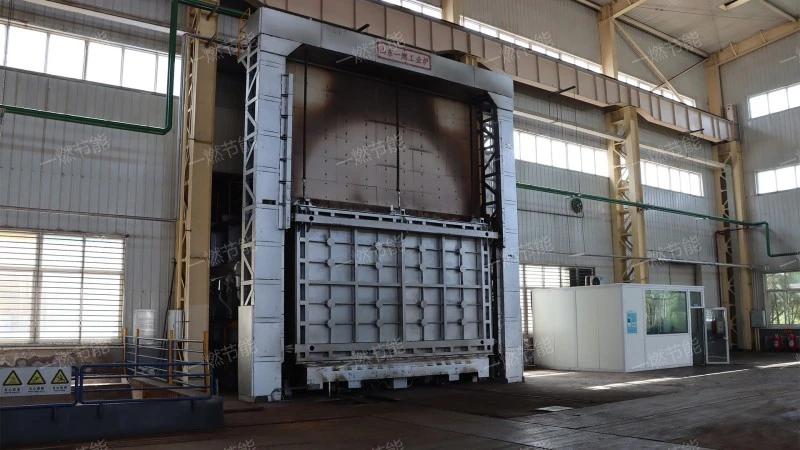

End in end out step heat treatment furnace

2、End in end out step heat treatment furnace application

The purpose of End in end out step heat treatment furnace is introduced as follows:

- Metal melting and casting

- Energy conservation and environmental protection

- Metal forging heating

- Metal heat treatment

- Metal forging heating

Although it is mainly used for forging heating, some types of End in end out step heat treatment furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The End in end out step heat treatment furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The End in end out step heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, End in end out step heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The End in end out step heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

End in end out step heat treatment furnace

3、Video analysis of End in end out step heat treatment furnace

Speak directly with facts on the spot。

End in end out step heat treatment furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd is a popular End in end out step heat treatment furnace。

4、End in end out step heat treatment furnace use

End in end out step heat treatment furnaces have the following purposes.

- Improve production efficiency

- Metal melting and casting

- Metal heat treatment

- Metal tempering

- Energy conservation and environmental protection

The End in end out step heat treatment furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Although it is mainly used for forging heating, some types of End in end out step heat treatment furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, End in end out step heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the End in end out step heat treatment furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The End in end out step heat treatment furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

End in end out step heat treatment furnace

5、End in end out step heat treatment furnace characteristics

The End in end out step heat treatment furnace features are as follows:

- Strong adaptability

- Efficient heating

- Easy to control

- Easy to maintain

- energy saving and environmental protection

The End in end out step heat treatment furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The End in end out step heat treatment furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The combustion system and ventilation system of the End in end out step heat treatment furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The structural design of the End in end out step heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the End in end out step heat treatment furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

End in end out step heat treatment furnace

6、Brief introduction of End in end out step heat treatment furnace

End in end out step heat treatment furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

End in end out step heat treatment furnace

End in end out step heat treatment furnacethe product looks beautiful.,the principle is simple.The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.。

Related recommendation

-

What is a Metal Heat Treatment Gas Trolley Stove? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Aluminum forging heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Pit type reduction furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Automated natural gas trolley furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

台车式低温加热炉

2023-07-20 -

Introduction to High temperature chain grate furnace and heating furnace advantages and features

2025-5-27 -

What is a Dual station annealing heat treatment furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Electric heating industrial annealing furnace, Trolley electric heating furnace specifications, model parameters

2025-5-27 -

Introduction to Circular Well Heating Furnace, heating furnace specifications, model parameters

2025-5-27 -

What is a Through type mold shell roasting furnace? Introduction to the principle of Forging furnace structure

2025-5-27