Introduction to Tool steel heating furnace, heating furnace specifications, model parameters

Tool steel heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.,support customization。The following is to introduce the Tool steel heating furnace:

1、Brief introduction of Tool steel heating furnace

Tool steel heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.。

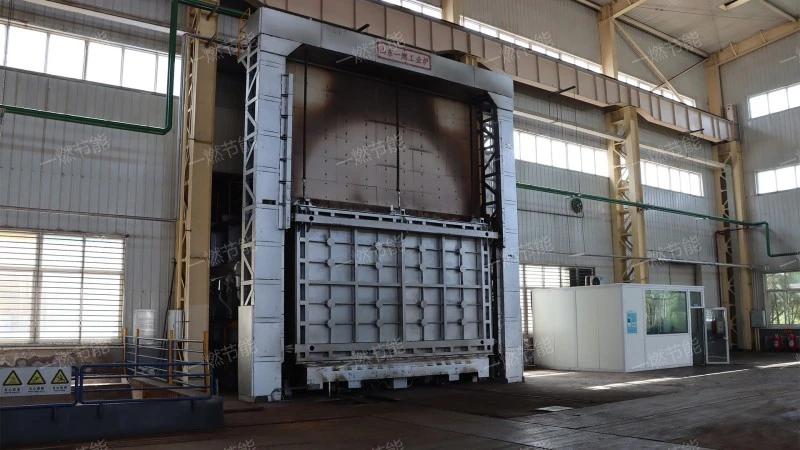

Tool steel heating furnace

2、Working principle of Tool steel heating furnace

Tool steel heating furnaceHeat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,it has the structure of recovery of waste heat, ventilation system, ventilation system, furnace chamber and ventilation system。

Tool steel heating furnace

3、Tool steel heating furnace introduction video

Speak directly with facts on the spot。

Tool steel heating furnace

As you can see from the live video.,One-combustion energy saving The overall structural design is simple and novel.,it mainly includes ventilation system, convection chamber, recovery of waste heat, Radiation chamber and combustor。

4、Tool steel heating furnace characteristics

The Tool steel heating furnace features are as follows:

- Easy to control

- Efficient heating

- energy saving and environmental protection

- Strong adaptability

- Easy to maintain

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The Tool steel heating furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Tool steel heating furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The Tool steel heating furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

The structural design of the Tool steel heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Tool steel heating furnace

5、How much is the Tool steel heating furnace?

The Tool steel heating furnace price is introduced as follows:

- Product configuration difference

- marketing channel

- market supply and demand

- geographical position

- specifications and models

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

With the increasingly fierce competition of Tool steel heating furnace, market factors have a certain influence on the price of Tool steel heating furnace. When the demand in the market increases and the supply remains unchanged, the price will rise. On the contrary, the price will fall. When there is an increase in supply and the demand remains unchanged, the price will rise, on the contrary, the price will fall.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

There are various specifications and models of Tool steel heating furnace, and the performance of different specifications and models is quite different. Customers should choose products with appropriate specifications and models according to the actual situation.

Tool steel heating furnace

6、Company service

Jinan, Shandong province One-combustion energy saving Factory is a large-scale Tool steel heating furnace manufacturer and seller, producing a wide range of Tool steel heating furnace with complete models. Choose One-combustion energy saving, I believe you will never regret it. One-combustion energy saving has a mature after-sales team to follow up and serve, ensuring the peace of mind of buying and using. Welcome to Jinan One-combustion energy saving factory for on-the-spot investigation. I provide free pick-up service.。

One-combustion energy saving

Tool steel heating furnaceit has the functions of Casting heating, anneal, normalizing, normalizing and anneal,it has the characteristics of Easy to control, Strong adaptability, energy saving and environmental protection, energy saving and environmental protection and energy-efficient。

Related recommendation

-

What is a Denitrification of flue gas inside the furnace? SCR denitration specifications, models, and parameters

2025-5-27 -

What is a Multi functional through forging heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to SCR catalytic oxidation flue gas denitrification equipment and SCR denitration system structure principle

2025-5-27 -

Introduction to Metal industry resistance heating furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

Introduction to Full fiber annealing trolley forging furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Steel chain iron core annealing furnace, how much is the price of the forging furnace?

2025-5-27 -

高温台车锻造炉

2023-07-29 -

What is a Plate chain roasting furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Medium carbon steel heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Side entry and side exit stepper industrial furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27