What is a Spheroidization annealing heat treatment furnace? heating furnace specifications, models, and parameters

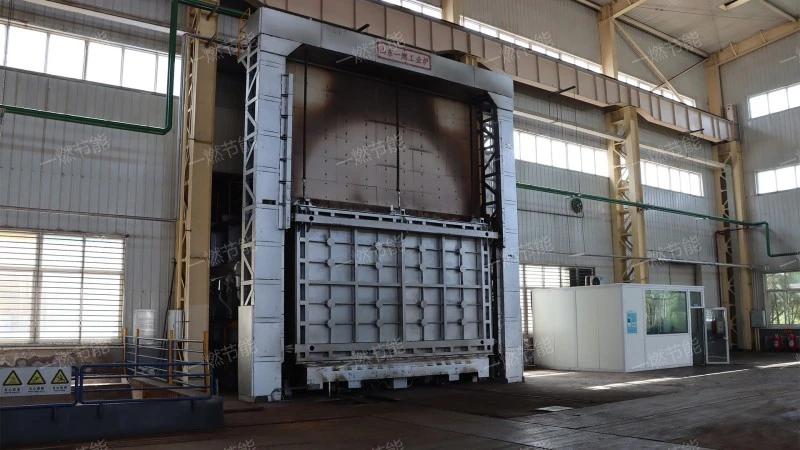

Spheroidization annealing heat treatment furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the product looks beautiful.。The following is to introduce the Spheroidization annealing heat treatment furnace:

1、Brief introduction of Spheroidization annealing heat treatment furnace

Spheroidization annealing heat treatment furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,is a kind of high quality and low price Spheroidization annealing heat treatment furnace,it has the functions of Casting heating, Forging heating, Casting heating, quench and anneal。

Spheroidization annealing heat treatment furnace

2、Spheroidization annealing heat treatment furnace function

Spheroidization annealing heat treatment furnacemultifunctional, with functions such as heat treatment, normalizing, Forging heating, hardening and tempering and temper,It can be used for Metal melting and casting, Improve production efficiency, Energy conservation and environmental protection, Metal tempering, Improve production efficiency, Metal forging heating and so on,it is usually composed of combustor, Radiation chamber, recovery of waste heat, convection chamber and ventilation system,Spheroidization annealing heat treatment furnaceThe structural design is simple, novel and special.,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,be loved by our customers.。

Spheroidization annealing heat treatment furnace

3、Spheroidization annealing heat treatment furnace principle

Spheroidization annealing heat treatment furnaceat runtime,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Spheroidization annealing heat treatment furnace

4、Spheroidization annealing heat treatment furnace application

Spheroidization annealing heat treatment furnaces have the following purposes.

- Improve production efficiency

- Metal melting and casting

- Energy conservation and environmental protection

- Metal tempering

- Energy conservation and environmental protection

The Spheroidization annealing heat treatment furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Although it is mainly used for forging heating, some types of Spheroidization annealing heat treatment furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Spheroidization annealing heat treatment furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

By properly heating and cooling the metal material, the Spheroidization annealing heat treatment furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Spheroidization annealing heat treatment furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

Spheroidization annealing heat treatment furnace

5、How much is the Spheroidization annealing heat treatment furnace?

The Spheroidization annealing heat treatment furnace price is introduced as follows:

- cost of production

- specifications and models

- technology content

- Company size

- select a qualified person

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

There are various specifications and models of Spheroidization annealing heat treatment furnace, and the performance of different specifications and models is quite different. Customers should choose products with appropriate specifications and models according to the actual situation.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

The nature of the manufacturer can also greatly affect the price of the Spheroidization annealing heat treatment furnace. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

The quality of material selection is one of the main factors that directly affect the Spheroidization annealing heat treatment furnace. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

Spheroidization annealing heat treatment furnace

6、company strength

The company has many years of Spheroidization annealing heat treatment furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Spheroidization annealing heat treatment furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it can be used in chemical industry, petroleum, automobile, material, war industry and other industries。

Related recommendation

-

Introduction to Aluminum alloy casting electric furnace, introduction to Trolley electric heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Pull rod annealing furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Continuous trolley forging furnace and forging furnace working principle

2025-5-27 -

Introduction to Low temperature tube quenching furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Carburizing quenching heat treatment furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

What is a Aluminum alloy high-temperature trolley forging heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Dual car high-temperature test furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Aluminum alloy furnace for trolley, forging furnace specifications, model parameters

2025-5-27 -

What is a Direct fired annealing heat treatment furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Industrial heat treatment heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27