Introduction to Automatic Annealing Furnace and heating furnace advantages and features

Automatic Annealing FurnaceIt is a forging heating device using gas as fuel.,at runtime,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,it has the characteristics of Stable and reliable, energy saving and environmental protection, energy-efficient, Easy to maintain and Easy to control,the principle is simple.The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,generally, it is composed of furnace chamber, convection chamber, recovery of waste heat, Radiation chamber, combustor and other major components,This Automatic Annealing FurnaceSimple structure and reliable operation.。The following is to introduce the Automatic Annealing Furnace:

1、Brief introduction of Automatic Annealing Furnace

Automatic Annealing FurnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it has the functions of Forging heating, temper, anneal, heat treatment and normalizing。

Automatic Annealing Furnace

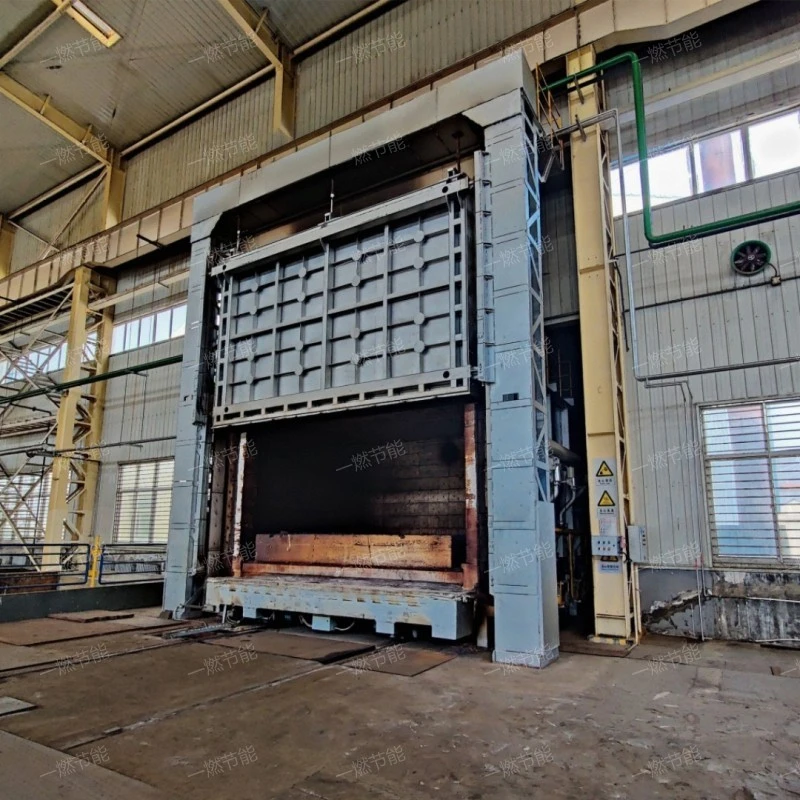

2、Automatic Annealing Furnace HD picture

Provide a variety of specifications and models of Automatic Annealing Furnace, high-definition picture list.。

Automatic Annealing Furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Automatic Annealing Furnace use

The purpose of Automatic Annealing Furnace is introduced as follows:

- Energy conservation and environmental protection

- Metal tempering

- Metal forging heating

- Improve production efficiency

- Energy conservation and environmental protection

The Automatic Annealing Furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

By properly heating and cooling the metal material, the Automatic Annealing Furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Automatic Annealing Furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Automatic Annealing Furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Automatic Annealing Furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

Automatic Annealing Furnace

4、Automatic Annealing Furnace function

Automatic Annealing Furnacemultifunctional, with functions such as hardening and tempering, quench, Casting heating, temper and heat treatment,the product looks atmospheric.,It is mostly used in Improve production efficiency, Metal tempering, Metal heat treatment, Energy conservation and environmental protection, Metal melting and casting, Metal forging heating and so on,widely used in electron, chemical industry, automobile, war industry, metallurgy and other fields,it is an ideal choice for customers to buy Automatic Annealing Furnace。

Automatic Annealing Furnace

5、Automatic Annealing Furnace introduction video

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Automatic Annealing Furnace production process and production site, and gain favorable comments and recognition from customers.。

Automatic Annealing Furnace

As you can see from the live video.,One-combustion energy saving the product looks atmospheric.。

6、Company preferential activities

Automatic Annealing Furnace is a new type of heating furnace introduced by Shandong yiran energy-saving environment protection co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for aerospace and other industries. Now consult One-combustion energy savingProduction and processing的Automatic Annealing Furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Automatic Annealing FurnaceIt can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.,it is widely used inshipping,light industry,Household necessities,petroleum,heat treatment and other industries,It is a product series that integrates Metal tempering, Energy conservation and environmental protection, Metal heat treatment, Metal forging heating and Improve production efficiency。

Related recommendation

-

What is a Deep well heating annealing furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Tempering and tempering heating furnace and heating furnace advantages and features

2025-5-27 -

What is a Anchor chain annealing furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Full fiber annealing trolley heating furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Forging Heating Gas Trolley Furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to walking beam reheating furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Trolley type calcination furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Roller shaft industrial furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Multi functional trolley furnace and heating furnace advantages and features

2025-5-27 -

Introduction to SCR flue gas catalytic denitrification equipment and SCR flue gas denitrification structure principle

2025-5-27