What is a Segmented heat treatment furnace? Introduction to the Working Principle of heating furnace

Segmented heat treatment furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,It is mostly used in Energy conservation and environmental protection, Metal tempering, Metal forging heating, Improve production efficiency, Metal melting and casting, Metal melting and casting and so on,customizable。The following is to introduce the Segmented heat treatment furnace:

1、Brief introduction of Segmented heat treatment furnace

Segmented heat treatment furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it is widely used in Household necessities, machinery, light industry, pharmacy and chemical industry,it has the functions of heat treatment, anneal, Forging heating, hardening and tempering and quench,it is usually composed of combustor, recovery of waste heat, Radiation chamber, ventilation system and furnace chamber,Widely used in Improve production efficiency, Metal heat treatment, Metal forging heating, Energy conservation and environmental protection and Metal tempering。

Segmented heat treatment furnace

2、Segmented heat treatment furnace explanation video

Speak directly with facts on the spot。

Segmented heat treatment furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd It is an efficient, energy-saving and environment-friendly metal heating device.。

3、Introduction of Segmented heat treatment furnace characteristics

Segmented heat treatment furnace has the following characteristics

- Easy to maintain

- Stable and reliable

- energy saving and environmental protection

- Efficient heating

- Easy to control

The structural design of the Segmented heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Segmented heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Segmented heat treatment furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The Segmented heat treatment furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

The combustion system and ventilation system of the Segmented heat treatment furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Segmented heat treatment furnace

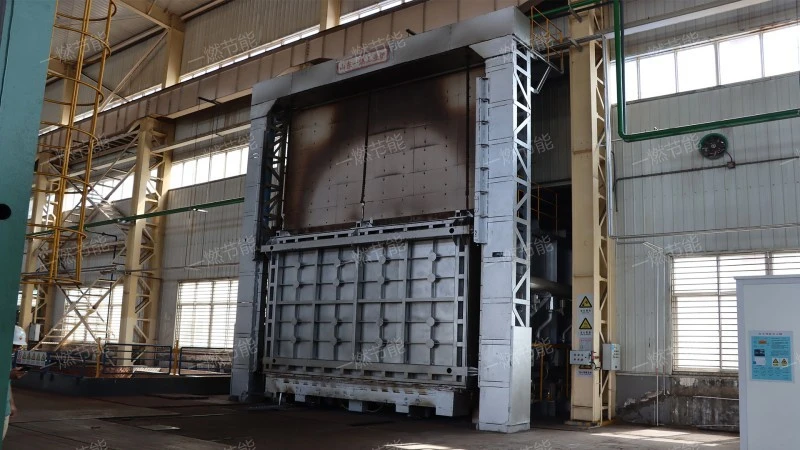

4、Segmented heat treatment furnace HD real picture

Segmented heat treatment furnace are widely used. The following is a multi-directional display diagram of Segmented heat treatment furnace, and the details are full of quality and intelligence.。

Segmented heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、How much is the Segmented heat treatment furnace?

The Segmented heat treatment furnace price is introduced as follows:

- raw material

- market factors

- service

- Low cost of raw materials

- Quality advantages and disadvantages

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

The Segmented heat treatment furnace market is always a fluctuating variable value. When the demand for this product in the market is far greater than the supply, the product price will be higher. On the other hand, when the market demand is much less than the supply, manufacturers are eager to sell their products and lower their prices appropriately.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Segmented heat treatment furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Segmented heat treatment furnace price can meet the purchasing needs of customers.

Production costs include raw material costs, labor costs, other costs, etc., which manufacturers need to invest when producing products, but these factors are not certain. They are affected by the market. When one factor in the market changes, the production costs of manufacturers will also change, and the price of Segmented heat treatment furnace will also fluctuate to some extent.

As we all know, the service life of products with excellent quality will be longer, and at the same time, the benefits created by such products for customers will be higher, which will lead to an increase in the cost of products and a high sales price of products.

Segmented heat treatment furnace

6、One-combustion energy saving's after-sales service

One-combustion energy saving adheres to the service concept of "being honest, doing things according to rules, pioneering and innovating, mutual benefit and win-win", and serves every customer wholeheartedly to create quality products and intimate services for customers.。

One-combustion energy saving

Segmented heat treatment furnaceat the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,the main structure includes furnace chamber, Radiation chamber, convection chamber, recovery of waste heat, ventilation system and so on,This Segmented heat treatment furnaceThe overall structural design is simple and novel.,the product looks beautiful.。

Related recommendation

-

Introduction to Preheating heat treatment industrial furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Spheroidization annealing heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Steel pipe heating furnace flue gas denitrification system? Introduction to the advantages, characteristics, and principles of the SCR denitration system

2025-5-27 -

What is a Resistance steel pipe annealing furnace? How much is the price of the Trolley electric furnace?

2025-5-27 -

Introduction to Fully automatic well type heating furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Automated deep well furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

What is a Industrial furnace for carburizing heat treatment? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Quenching heat treatment industrial furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Trolley forging resistance furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

Introduction to High temperature forging furnace, how much is the price of the Forging furnace?

2025-5-27