What is a Step by step quenching and tempering furnace? Introduction to the Working Principle of forging furnace

Step by step quenching and tempering furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,It has the functions of Metal melting and casting, Metal tempering, Metal heat treatment, Metal forging heating and Improve production efficiency,is a common Step by step quenching and tempering furnace。The following is to introduce the Step by step quenching and tempering furnace:

1、Brief introduction of Step by step quenching and tempering furnace

Step by step quenching and tempering furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

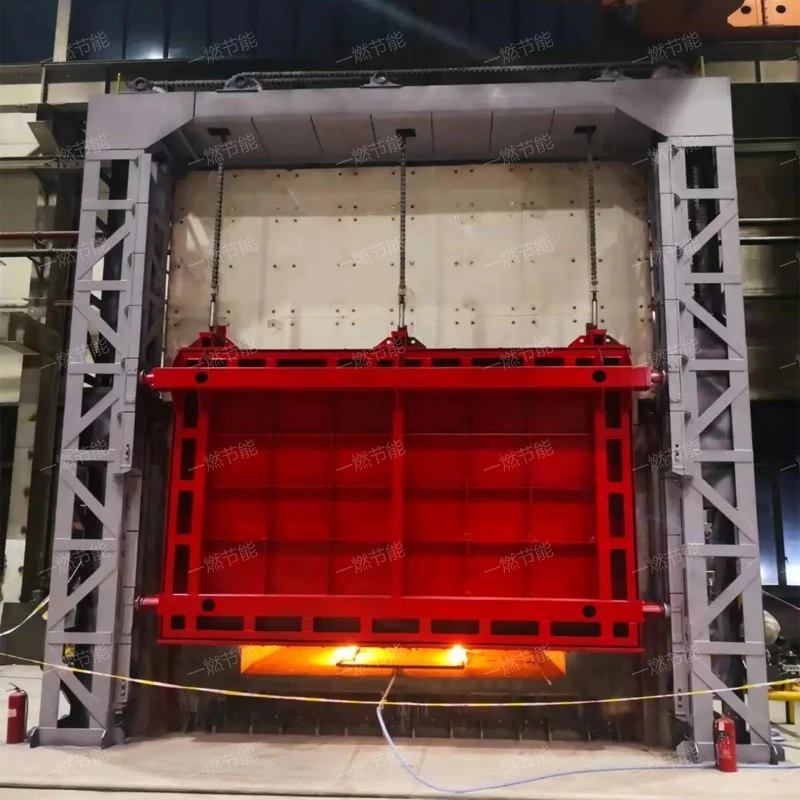

Step by step quenching and tempering furnace

2、Advantages of Step by step quenching and tempering furnace principle

Step by step quenching and tempering furnaceat work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,is designed by One-combustion energy saving with advanced technology。

Step by step quenching and tempering furnace

3、Introduction of advantages of Step by step quenching and tempering furnace

The advantages of Step by step quenching and tempering furnace are as follows:

- Wide application range

- Extend the service life of equipment

- clean energy

- Multiple fuel options

- clean energy

The Step by step quenching and tempering furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

The Step by step quenching and tempering furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

Although the Step by step quenching and tempering furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

Step by step quenching and tempering furnace

4、Introduction of Step by step quenching and tempering furnace characteristics

Step by step quenching and tempering furnace has the following characteristics

- Easy to maintain

- energy saving and environmental protection

- Stable and reliable

- Strong adaptability

- energy saving and environmental protection

The structural design of the Step by step quenching and tempering furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Step by step quenching and tempering furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The Step by step quenching and tempering furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Step by step quenching and tempering furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Step by step quenching and tempering furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

Step by step quenching and tempering furnace

5、Step by step quenching and tempering furnace function

Step by step quenching and tempering furnacemultifunctional, with functions such as Casting heating, normalizing, hardening and tempering, Forging heating and Casting heating,Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.,it has the characteristics of energy-efficient, energy saving and environmental protection, Easy to maintain, Stable and reliable and Easy to control。

Step by step quenching and tempering furnace

6、One-combustion energy saving introduced

One-combustion energy saving, as one of the professional and powerful Step by step quenching and tempering furnace manufacturers in Jinan, produces Step by step quenching and tempering furnace with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

One-combustion energy saving

Step by step quenching and tempering furnaceit has the functions of heat treatment, hardening and tempering, anneal, normalizing and quench,features include Strong adaptability, Stable and reliable, energy saving and environmental protection, Easy to control and Easy to maintain。

Related recommendation

-

Introduction to SCR flue gas denitrification system, introduction to SCR denitration advantages and characteristics

2025-5-27 -

Introduction to Flue gas denitrification equipment in the forging industry, SCR denitration system specifications, model parameters

2025-5-27 -

Introduction to Dual car high-temperature annealing furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

What is a Gas tube heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Casting electric furnace and Trolley electric heating furnace advantages and features

2025-5-27 -

What is a Off furnace flue gas denitrification equipment? Introduction to the advantages, characteristics, and principles of the SCR flue gas denitrification

2025-5-27 -

Introduction to Natural gas thermal storage tubular roaster, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Regenerative natural gas walking furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Industrial well type heating furnace and forging furnace advantages and features

2025-5-27 -

What is a Segmented annealing heat treatment furnace? Introduction to the Working Principle of forging furnace

2025-5-27